Industrial Wastewater Waste Water Treatment Plant Inclined Sloping Tube Settler Settling Tank Lamella Clarifier for Food Processing Water Treatment

Basic Info

| Model NO. | QDLC |

| After-sales Service | Lifelong |

| Warranty | 1 Year |

| Type | Flotation Machine |

| Method | Combined Treatment |

| Usage | Industrial, Home, Agriculture, Hospital, Hotels, Garment Shops, Building Material Shops, Ma |

| Marketing Type | Hot Product |

| Function | Remove Cod BOD |

| Application | Wastewater Clarification,Water Purification |

| Certification | ISO/CE/SGS/BV |

| Core Components | Motor, PLC, Valve |

| Flow Rate | 1m³/H-200m³/H |

| Power | According to The Capacity or Customized |

| Voltage | 220V/ 380V/ Customerized |

| Control | Electric Auto Control PLC Siemens/Manaul |

| Material | Anti-Corrosion Carbon Steel or SS304 |

| Padding | PP/PVC/FRP |

| Size | According to The Capacity or Customized |

| Color | Grey/Silver/Blue/Balck/Customerized |

| Machinery Test Report | Provided |

| Video Outgoing-Inspection | Provided |

| Transport Package | Standard Shipping Package |

| Specification | Inclined Tube Lamella Settling Tank/Lamella Clarif |

| Trademark | QDEVU or Customized |

| Origin | China |

| HS Code | 8421219990 |

| Production Capacity | 30/Month |

Product Description

Description

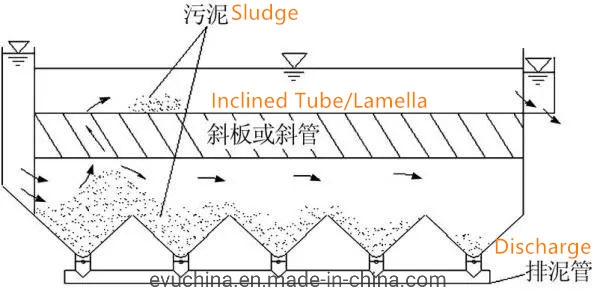

Lamella clarifier or inclined plate settler (IPS) is a type of settler designed to remove particulates from liquids. They often employed in primary water treatment in place of conventional settling tanks. used in industrial water treatment. inclined plates provide a large effective settling area for a small footprint. The inlet stream is stilled upon entry into the clarifier. Solid particles begin to settle on the plates and begin to accumulate in collection hoppers at the bottom of the clarifier unit. Sludge drawn off at the bottom of the hoppers and the clarified liquid exits the unit at the top over weir.

Application

Primary clarification of wastewater streamsBackwash water recoveryIndustrial water treatment systems Potable water treatment systemsRiver water abstraction clarificationWash water recovery and recirculation systems Wet scrubber and slaking effluent treatment

Working Principle

According to the principle of shallow pond, the effective volume of sedimentation tank is certain. The larger the area of the sedimentation tank is, the higher the sedimentation efficiency of the sedimentation tank is, which has nothing to do with the sedimentation time. The shallower the sink, the shorter the settling time. The sedimentation area of the inclined tube packing sedimentation tank is separated into thin layers by a series of parallel inclined plates or inclined tubes, which embodies the principle of shallow pool.

The inclined plate sedimentation tank adopts the principle of "shallow layer precipitation" to shorten the sedimentation distance of particles, thus shortening the sedimentation time, and increasing the sedimentation area of the sedimentation tank, thus improving the treatment efficiency.

Main Feature

*Simple structure,without wearing parts,wear well,decrease maintenance *Steady operation,easy operation *Small power,save energy*Small occupy area, low investment, high efficient*Short retention time, high sediment efficiency, no sludge backflow.Application

*Electroplate effluent contain many kinds of metal ion, cr,cu,Fe,Zn ,Ni etc remove rate all above 90%, after treatment, all can reach discharge standard. *Coal mine,mineral processing waste water all can make the turbidity from 500-1500 mg/L reduce to 5 mg/L. *Printing and dyeing,bleach and dye etc effluent chroma removing rate reach 70~90%,COD remove rate 50-70%.*Tannery ,food etc industrial sewage and construction site sewage COD remove rate 50~80%, impurity solids remove rate above 90%. *Chemical waste water COD remove rate 60~70%, chroma removal rate 60~90%, suspended solids reach discharge standard. *River water,remove rate about 95%.*All kind of industrial wastewater pretreatment.

Packaging & ShippingCompany Profile

Our Company

Qingdao EVU Environmental and Engineering Equipment is established in 1999,it is one of scientific research design, equipment manufacture, installation, commissioning and training services as one integrated technology-oriented enterprises in water treatment industry. It is holding by Qingdao Spark Textile Machine which is a national Spark Industrial Group, national second-level and large-scale comprehensive enterprise group in China.Our Products

We use the advanced technology and equipment over the world. Our main productions: Integrated Sewage Treatment Equipment, MBR Sewage Treatment Equipment(MBR), Electrocoagulation Sewage Treatment Plant(EC Plant), Reverse Osmosis Filteration Equipment(RO System), Dissolved Air Flotation Machine(DAF), Cavitation air Flotation Machine(CAF), Aerator, Screw Press Sludge Dewatering Machine, Automatic Chemical Dissolved and Dosing machine, Sludge Scraper, Slag Scraper, The micro bubble generator, USAB anaerobic reactor, Bar Screen, Sand Filter and so on series products.Our Customers

We have professional engineer support, high efficiency sales team and competitive price superiority, and attract customers from all over the world, we export to over 40 countries, including Europe, Poland, Serbia, Uruguay, Turkey, Russia, USA, Mexico, Brazil, Singapore, India, Egypt, Thailand, Middle east and South Africa.Our Certificate

We based on "technological development, pollution remediation, wholeheartedly for customer services". We hope to cooperate with all customers from all over the world and build a better world together.FAQQ1:Are you a factory or trading company?

We are a real manufacturer who can offer you both the most competitive price and top quality products.

Q2:Where is your factory located? How can I visit there?

Our factory is located in Qingdao City Shandong Province, All our clients, from home or abroad, are warmly welcome to visit us!

Q3:Can you put my company brand (logo) on the products?

Yes,we support OEM/ODM service,the customize process as follows:1.Customers put forward personalized customization requirements.2.Our engineer draw the design draft.3.Customer confirm the design draft.4.Factory start to produce shipment.

Q4:How to select right model?

You can tell us what you need, and we can help you choose the Model.Basic informations as follows:Wastewater type : Industry wastewater, Domestic wastewater, food wastewater or others)Capacity:m³/Day or m³/Hour?Raw water quality: SS, Oil & Grease &Fat & FOG, PH,BOD,COD content?Output water quality standard,for discharge or reuse?Local voltage and frequency?

Q5: What is your MOQ?

Normally, our MOQ is 1 set.

Q6:What is the payment term ?

TT and L/C are acceptable and TT will be more appreciated, 30% deposit, 70% balance payment before shipment.

Q7: We haven't imported before, can you ship the goods to our warehouse?

Yes. Although our normal trade term is EXW, FOB, CIF, we can also arrange logistics to your warehouse.

Q8:What is the delivery time of your factory?

5-10 days for general series products, meanwhile, batches products & customized products would need 15-30 days based on different situations.Contact us for the exact time.

Q9:How do you ensure the quality of your products?

Generally, our equipment are the most durable type in the industry, this is also the feature of the label impression for most of our customers at home or abroad.Skilled workers and strict quality control system can ensure every machine with best working performance.

Q10:How to assemble the equipment once we received it?

The CAD install instruction, assembly procedure and project case will be provided.,Of course our skilled installation engineers would go to your country and install the equipment if needed.

Q11: What is your product warranty ?After sales service?

The warranty is 12 months while the lifetime is 10-15 years under good maintenance.It is durable and anti-corrosion.Provide equipment certification and installation operating instructions.Provide one-year spare parts.Provide technical advisory services.Provide guidance staff for installation and commissioning.