Bogda Chemical Additives Auto Dispensing System Plastic Powder Auto Dosing Machine

Basic Info

| Model NO. | Bog-ASM2 |

| Working | Automated Batching |

| Stirring Type | Auto Dispensing |

| Application | Powder |

| Certification | CE |

| Application Area | Plastic |

| Layout Type | Verticle |

| Mixing Drum Shape | Disc |

| Additional Capabilities | Drying |

| Operating type | Cycle Operating |

| Condition | New |

| Voltage | 380V 50Hz 3phase or Customised |

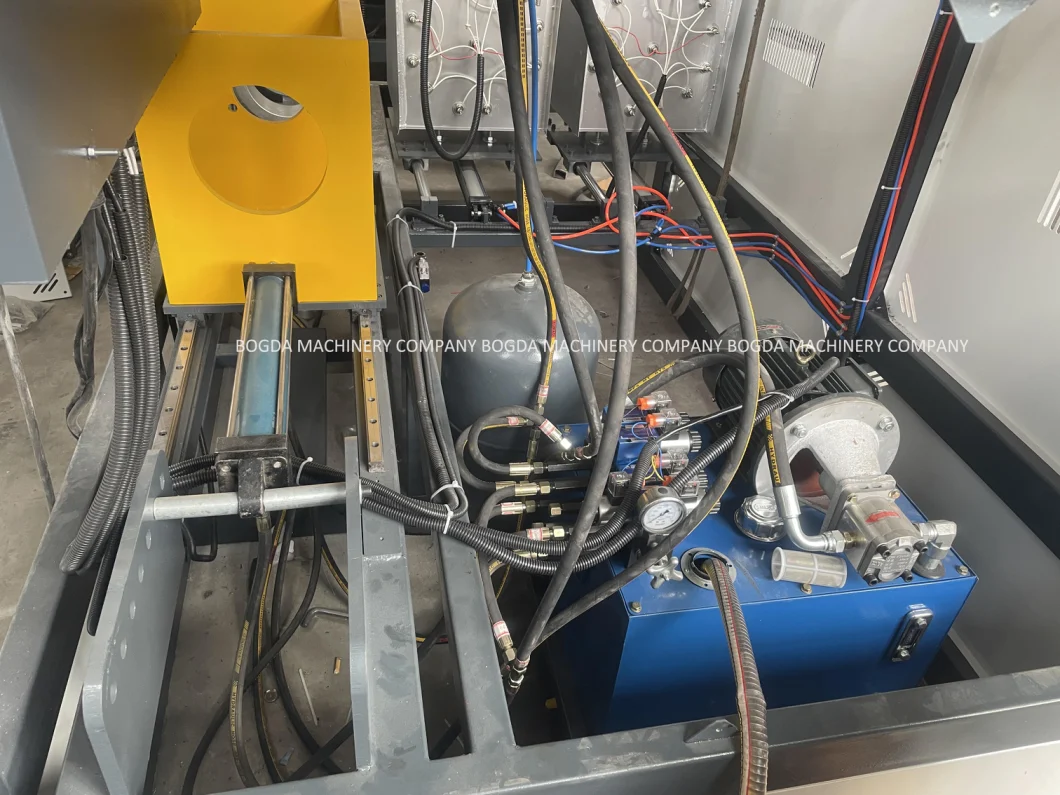

| Core Components | Pressure Vessel, Motor, Gearbox, Engine |

| Output (Kg/H) | 300 - 400 |

| Power (Kw) | 85 |

| Automatic Weighting | Electronic Balance Sensor |

| Heating Mixing Time | 15-20 Minutes |

| Auto Dosing Loading Control | by Inverter |

| Dimension(L*W*H) | 5000*5800*3200 |

| Weight (Kg) | 9000 Kg |

| Loading Method | Vacuum Loading |

| Cooling Method | 8 Minutes |

| Transport Package | Film Packaging and Plywood Case Packaging |

| Specification | 7500cm*1400cm*1750cm |

| Trademark | Bogda |

| Origin | China |

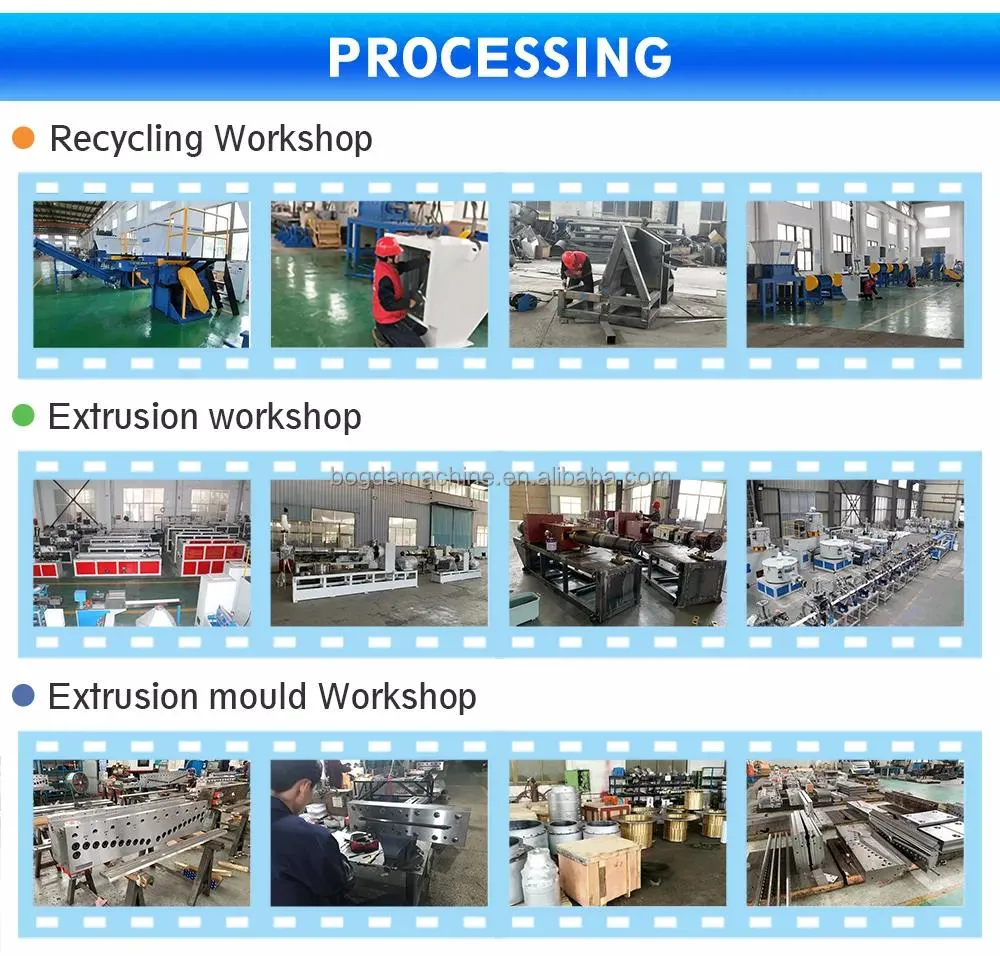

| Production Capacity | 300 Set/Sets Per Month |

Packaging & Delivery

Package size per unit product 5000.00cm * 5800.00cm * 3200.00cm Gross weight per unit product 9000.000kgProduct Description

Bogda Chemical Additives Auto Dispensing System Plastic Powder Auto Dosing Machine

The "Auto Dosing Machine" is a device used for accurate and automated dosing of various materials or substances in industrial processes. Its purpose is to precisely measure and dispense specific quantities of ingredients or components according to predefined formulas or recipes.

Advantages of an Auto Dosing Machine include:

-- Accuracy:The machine ensures precise dosing, minimizing errors in ingredient quantities and improving product consistency.-- Efficiency: It automates the dosing process, reducing manual labor and saving time and effort. It can handle high volumes of dosing tasks efficiently.-- Consistency: The machine delivers consistent dosing results, eliminating variations caused by human error or fatigue.-- Flexibility: It can be programmed to handle different types of materials and adjust dosing parameters based on specific requirements.-- Traceability: The machine often incorporates data recording and tracking capabilities, enabling traceability of dosing operations for quality control and regulatory compliance.-- Waste Reduction: By precisely measuring and dispensing materials, it helps minimize waste, optimize material usage, and reduce costs.-- Safety: The automation reduces the risk of exposure to hazardous materials, ensuring a safer working environment.-- Productivity: With automated dosing, the machine enhances overall production efficiency and throughput.Overall, the Auto Dosing Machine offers improved accuracy, efficiency, consistency, and safety in the dosing process, contributing to enhanced productivity and quality in industrial settings.

1. How many electric, water, air need for the machines?

BOGDA: technical department supply the whole layout for workshop details.

2. Can I operate machine if don't have experienced engineers?

BOGDA: (1) short-time engineers to customer company (5-15 days)

(2) Year-time working as requirements

3. Any quality checking before shipment?

BOGDA: 100% confirm, run and test machines before shipment with quality certificate.

4. How long is the guarantee?

BOGDA: 12 months since the first day customer operates (except wear parts)

5. How can u help us when face some technical problem?

BOGDA: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

6. Where can we get spare part?

BOGDA: we choose International Brand that customer can find it in everywhere, such as Siemens,Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.